Galvanized products

Galvanized products are coated with a zinc layer, which provides robust corrosion protection. They are widely used in various industries, including construction, automotive, and appliances, due to their durability and reliability. Additionally, galvanized products are easy to maintain and offer a cost-effective solution for corrosion prevention.

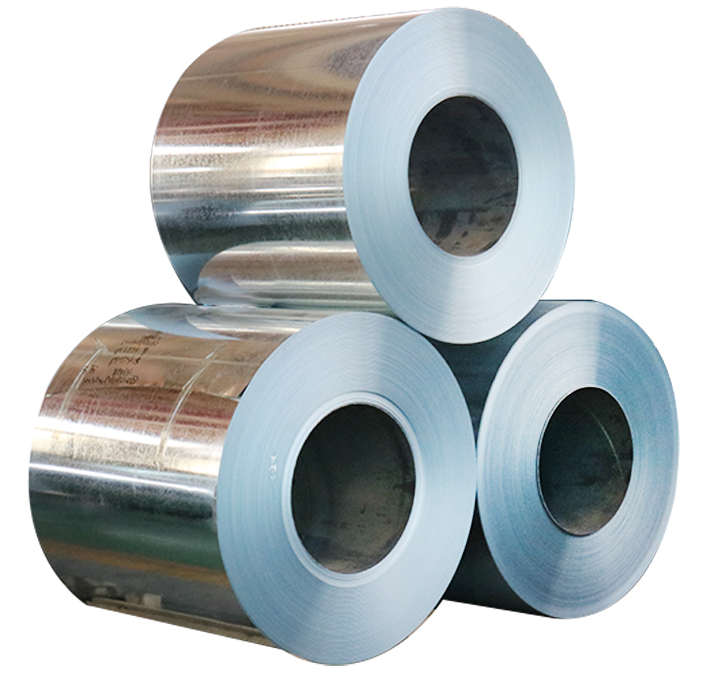

Galvanized coil

Galvanized coil, also known as galvanized steel coil, is a metal material covered with a zinc layer on the surface of a cold-rolled or hot-rolled steel plate. This zinc layer is formed by the hot dip plating process or electroplating process, which provides excellent corrosion resistance and durability of the steel plate. Galvanized coil not only has good corrosion resistance, but also its surface is smooth, beautiful, easy to process and form.

Galvanized coil has a wide range of applications in many industries such as construction, automobiles, home appliances, and packaging. In the field of construction, it is often used to make roofs, wall panels, ceilings, etc., and as a material for ventilation pipes and drainage pipes. In automobile manufacturing, galvanized coil is used for the production of body, chassis and other components. In addition, it also plays an important role in the manufacture of home appliances and the production of packaging containers.

Advantages of galvanized coil include:

Strong anti-corrosion: the zinc layer can effectively prevent the corrosion of the steel plate and extend its service life.

Good processing performance: the surface of the galvanized coil is smooth, easy to shear, bend, welding and other processing.

High aesthetics: galvanized coil appearance beautiful, uniform color, suitable for a variety of decorative purposes.

Economical: Compared with other anti-corrosion materials, galvanized coil has a higher cost performance.

In short, galvanized coil, as an important metal material, plays an irreplaceable role in modern industrial production and construction.

Galvanized pipe

Galvanized pipe, also known as galvanized steel pipe, is a steel pipe with a galvanized surface. The production process involves dipping the steel pipe into the molten zinc liquid to attach a zinc layer to the surface of the steel pipe to achieve the purpose of corrosion prevention and rust prevention. This galvanized treatment not only improves the corrosion resistance of the steel pipe, but also enhances its service life.

Galvanized pipes are favored for their excellent properties and wide range of applications. In the construction industry, galvanized pipes are often used in water and gas transmission pipelines, and as structural materials such as wire bushings, scaffolding, Bridges, and road guardrails. In addition, in the chemical industry, electric power, communications, transportation and other fields, galvanized pipes also play an important role.

The advantages of galvanized pipe include corrosion resistance, high temperature resistance, high strength, easy processing, etc. At the same time, its surface is smooth, beautiful, easy to clean and maintain. However, it should be noted that when using galvanized pipes, contact with acidic or alkaline substances should be avoided so as not to affect the quality and service life of its galvanized layer.

Industrial Valves

Home » Inquiry

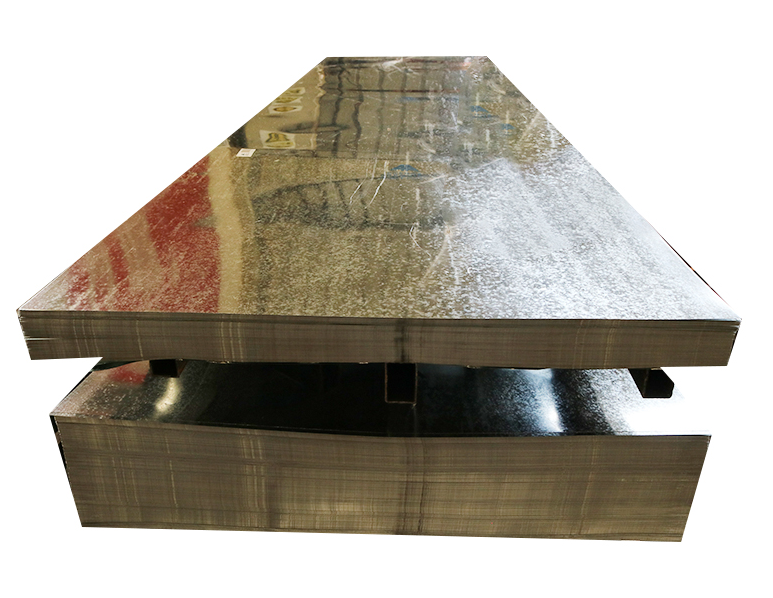

Galvanized sheet

Galvanized sheet, also known as galvanized steel sheet, is a metal material covered with a layer of zinc on the surface of the steel sheet. This zinc layer is usually formed by a hot-dip plating process, in which the steel plate is immersed in a molten zinc solution so that a zinc layer is attached to the surface. This treatment gives galvanized sheet excellent corrosion resistance and durability.

Galvanized sheet has many advantages, first of all, the zinc layer can effectively prevent the corrosion of the steel plate, thereby extending its service life. Secondly, the surface of the galvanized sheet is smooth and beautiful, and it is easy to carry out further processing and painting. In addition, it also has good weldability and machinability, which can meet the manufacturing needs of various complex shapes and structures.

Galvanized sheet is widely used in construction, automobile, home appliances, packaging and other fields. In the field of architecture, it is often used to make roofs, walls, partitions, etc., and as a material for ventilation pipes and drainage pipes. In automobile manufacturing, galvanized sheet is used in the production of body, chassis and other components to improve the corrosion resistance and safety of vehicles. In the home appliance and packaging industry, galvanized sheet also plays an important role, such as the manufacture of refrigerators, washing machines and other home appliances shell, as well as as a material for food packaging containers.

In short, galvanized sheet with its excellent corrosion resistance and durability, beautiful appearance and good processing performance, has become an indispensable important material in the field of modern industrial production and construction.

Galvanized strip

Galvanized strip steel is a galvanized steel, the production process is usually cold rolled or hot rolled long and narrow steel plate, through different galvanizing processes, on its surface covered with a layer of zinc. This zinc layer can be a pure zinc layer, or it can be an alloy layer of zinc with other metals, such as aluminum.

Galvanized strip steel has many advantages, such as uniform coating, strong adhesion and long service life. Hot dip galvanizing is one of the main galvanizing processes. In this process, complex physical and chemical reactions occur between the strip steel matrix and the molten bath to form a tight zinc-iron alloy layer with corrosion resistance. The alloy layer is integrated with the pure zinc layer and the strip matrix, which makes the galvanized strip steel have strong corrosion resistance.

Galvanized strip steel is a kind of steel product with excellent performance and wide application prospect.

Industrial Valves

Home » Inquiry

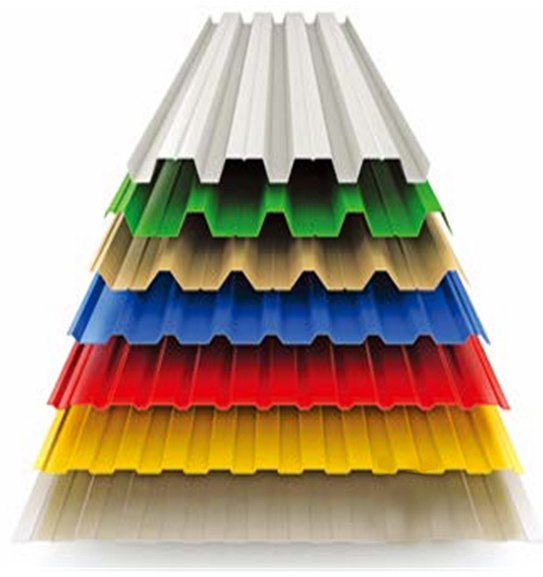

Galvanized corrugated steel plate

Galvanized corrugated steel plate is a special metal material that is covered with a zinc layer to protect the steel plate from corrosion. This material combines the corrosion resistance of galvanized sheet with the strength of corrugated sheet, with a range of advantages and a wide range of applications.

Galvanized corrugated steel has been widely used in construction, industry, agriculture and other fields. In the field of construction, it is often used as a covering material for roofs and walls, which can protect buildings from the erosion of rain, wind and snow and sunlight, and has a good waterproof, fire and corrosion prevention function. At the same time, its corrugated surface can also enhance the rigidity of the structure and improve the load-bearing capacity of the building. In addition, galvanized corrugated steel can also be used to make roof drainage systems, skylights, chimneys, fans and other building accessories. In the industrial field, galvanized corrugated steel is often used to make packing cases, pallets, shelves and other items, and its corrosion resistance and strength can meet the needs of various industrial environments. Galvanized corrugated steel is a kind of metal material with excellent properties and wide uses, which can meet the needs of various fields.

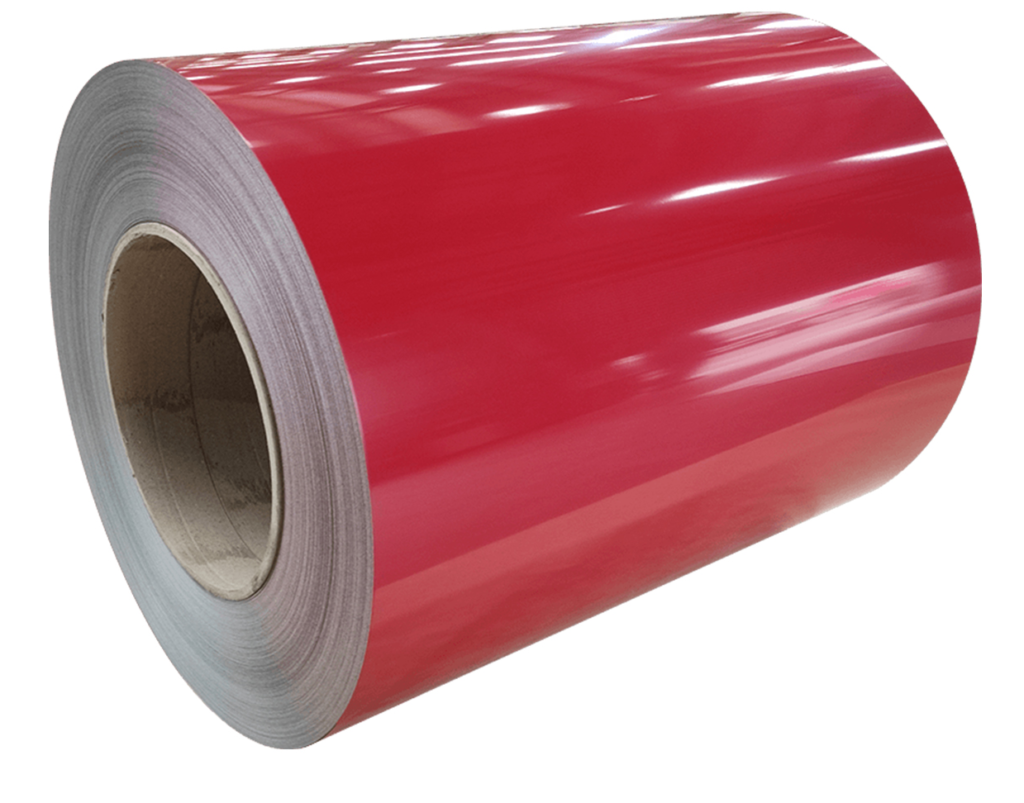

PPGI

Color coated coil, also known as color steel plate or color plate, is a kind of hot-galvanized plate, hot-plated aluminum zinc plate, electrogalvanized plate, etc., after surface pretreatment, coated with one or several layers of organic coating on the surface, and after baking and curing products. Because it is coated with a variety of different colors of organic coatings, the color steel coil is named, referred to as color coated coil.

The main characteristics of color coated coil include good durability, strong corrosion resistance, good heat resistance, excellent heat reflection, similar to galvanized steel plate processing performance and spraying performance, and excellent welding performance. These characteristics make the service life of the color coating roll longer than that of the galvanized strip, about 1.5 times. The coating used in the color coating volume can be selected according to the different use of the environment, such as polyester silicon modified polyester, polyvinyl chloride plastic sol, polyvinylidene chloride and so on. Users can choose according to specific needs and uses. Color coated coil is a kind of building material with excellent performance and wide application, and its beautiful, durable, anti-corrosion and other characteristics are favored by users.

Industrial Valves

Home » Inquiry

Color coated sheet

Color coated plate, also known as color coated steel plate or painted steel plate, is a building material used for decoration and protection of building exterior walls and roofs. Its base material is usually cold-rolled steel plate, galvanized steel plate or aluminum magnesium manganese alloy plate, etc., the surface is treated and then painted. The coating is generally made of polymer coatings, which can be selected in different colors and textures to meet different design needs.

Color coated board has many excellent characteristics, such as corrosion resistance, good weather resistance, convenient construction, beautiful and so on. Its diversity makes it possible to choose from suitable printing lines, colors and patterns for different use occasions. In addition, the color coated plate also has good processability, suitable for shearing, bending, rolling forming, stamping and other processing methods.

Color coated panels are widely used in construction, household appliances, transportation, furniture and other fields. For example, in the construction industry, color coated panels are often used in steel structure workshops, temporary offices and processing places; In the field of household appliances, color coated plate is often used as the shell of refrigerators, air conditioners and other equipment; In the transportation industry, automotive interior trim parts, tank bottom shells, etc., are also often color-coated.

In short, color coated board is a powerful and widely used building materials that can meet the needs of different fields.

Aluminized zinc magnesium plate

Aluminum zinc magnesium plate is a new type of coated steel plate with high corrosion resistance. Its coating composition is mainly zinc, and added an appropriate amount of aluminum, magnesium and trace silicon. The addition of these elements makes the aluminized zinc magnesium plate have excellent corrosion resistance, processing performance and self-healing function.

Specifically, zinc in the coating of aluminized zinc-magnesium plates provides sacrificial protection, aluminum provides passivation protection, and the addition of magnesium activates the alloy coating, further reducing the consumption rate of the coating. This special coating structure makes the aluminum zinc magnesium plate can form an isolated protective layer in the incision and section, and greatly improves the corrosion resistance of the plated steel.

Aluminized zinc magnesium plate has a wide range of applications. It mainly includes civil buildings (such as keel ceiling, porous plate, cable bridge, etc.), agricultural livestock production (such as agricultural feeding greenhouses steel structure, steel structure accessories, greenhouses, feeding equipment, etc.), railway roads, power communication (such as transmission and distribution high and low voltage switchgear, box type substation external body, etc.), automotive motors and industrial refrigeration (such as cooling towers, large outdoor industrial air conditioners, etc.) Karma.

In general, aluminum zinc magnesium plate with its high corrosion resistance, good processing properties and a wide range of applications, has become an indispensable new material in modern industry.

Look forward to cooperating with you!

We always want to make sure that our customers are getting the best deal, so let us know what you’re interested in and we’ll get back with a quote!