Industrial Valves

Home » Inquiry

High quality alloy rods produced in China

Alloy bars are composite materials that are utilized extensively in the manufacturing of machine parts and other industrial equipment. These bars are formulated by blending various metal and non-metal elements, resulting in engineering materials that exhibit exceptional strength, corrosion resistance, and other specialized properties. Alloy bars are crafted from processed alloy materials, making them a crucial component in the mechanical processing and manufacturing industries.

The diverse composition of alloy bars allows for the creation of products with tailored properties for specific applications. For instance, some alloy bars possess high tensile strength and ductility, making them suitable for use in aerospace components and other precision-engineered parts. Others exhibit excellent corrosion resistance, ideal for applications in harsh environments.

The manufacturing process of alloy bars involves precise mixing of the constituent elements and subsequent forming techniques such as rolling or extrusion. This ensures that the final product meets the rigorous standards required for use in various industries. Alloy bars are also often subjected to additional surface treatments to enhance their durability and performance.

In summary, alloy bars are indispensable in numerous industries due to their unique combination of properties and adaptability to specific application requirements.

Are you looking for quality steel?

Shandong Jindailai Steel Co., Ltd. is a manufacturer of carbon steel, galvanized steel, profiles and other types of steel manufacturers. Our factories comply with Chinese GB standards and customer specific requirements, products are sold all over the world, steel is widely used in construction, oil and other industries.

Subscribe For Newsletter

Sign up now for updates about early registration. A wonderful serenity taken possession into entire soul also like.

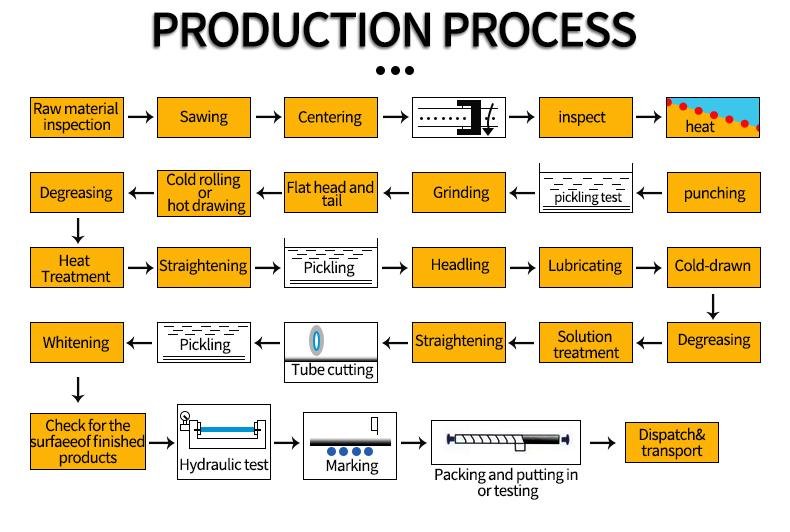

Technological process

The process of making alloy rods is a carefully controlled process. First, according to the required alloy composition, prepare the corresponding metal materials, which are usually prepared by powder metallurgy, to ensure the accuracy and uniformity of the alloy composition. Next, the raw material is heated in a furnace to melt it into a liquid metal, a process that requires controlled temperature and melting time. After the smelting is completed, the molten alloy liquid is poured into a mold of a specific shape for casting to form the initial shape of the alloy rod. Then, heat treatment, including annealing, solution, quenching and other processes, to improve the mechanical properties and structural stability of the alloy. Finally, the alloy rod is finished, such as cutting, deburring, grinding, etc., so that it can meet the specified size and appearance requirements. The entire production process requires strict control of the parameters of each link to ensure the quality and performance of the alloy rod.

Applied range

Alloy rods are used in many important fields because of their unique properties and wide applicability. In mechanical manufacturing, alloy rods are often used to manufacture key components such as bearings and gears because of their high strength, high hardness and wear resistance. In the aerospace field, the lightweight, high strength and high temperature tolerance of alloy rods can make them ideal materials for the manufacture of aircraft, rockets and other devices. In the energy industry, alloy rods are used to make energy equipment such as nuclear power plants and gas turbines that withstand extreme working conditions. In addition, alloy rods also play an important role in chemical, electronics and other fields, and are key materials to support and promote the development of these industries.

Industrial Valves

Home » Inquiry

Customized service

Our steel pipe products are tailored to meet the specific requirements of our customers. Whether it’s size, material thickness, or coating, we can tailor it to your unique needs. Shandong Jintai Lai takes pride in the quality of its products. We adhere to strict quality control standards to ensure that our steel pipes are durable, reliable and meet international standards. With many years of experience in the steel industry, we have the knowledge and expertise to provide you with the best solution. Our team of experts is ready to help you with any questions or concerns.

Corrosion resistance is a crucial factor in the selection of pipes for various applications. Our carbon steel pipes are treated with advanced corrosion-resistant coatings and finishes that provide superior protection against rust and other forms of corrosion. This ensures that our pipes maintain their structural integrity and performance over extended periods of use, even in corrosive environments. The corrosion resistance of our pipes significantly reduces maintenance costs and downtime, making them a cost-effective choice for long-term use.

High cost performance and quality service

We offer competitive prices for our steel pipe products, ensuring you get the best value for money. Our wholesale business model allows us to offer discounts for bulk orders, making it more cost effective for our customers.We believe that customer satisfaction is our top priority. Our team is committed to providing exceptional customer service, from initial consultation to after-sales support. We are always ready to help and ensure that your needs are met.

We understand that choosing the right pipes for your application is crucial, and we are committed to providing you with the necessary support and guidance. Our team of experts is available to assist you in selecting the most suitable pipes for your specific requirements. Additionally, we provide comprehensive after-sales support, including installation advice, troubleshooting, and maintenance recommendations. Our reliable customer support ensures that you have a smooth and satisfactory experience with our carbon steel pipes.

Industrial Valves

Home » Inquiry

FAQ

Q: CAN WE VISIT YOUR FACTORY?

A: WARM WELCOME. ONCE WE HAVE YOUR SCHEDULE, WE WILL ARRANGE A PROFESSIONAL SALES TEAM TO FOLLOW UP WITH YOU.

Q: WHAT ARE YOUR PAYMENT TERMS?

A: WE PREFER TT

Q: CAN YOU PROVIDE SAMPLES?

A:YES, THE SAMPLE OF NORMAL SIZE IS FREE, BUT THE BUYER HAS

TO PAY THE FREIGHT.

O: WHY DID YOU CHOOSE OUR COMPANY?

A:(1) WE HAVE MORE THAN 20 YEARS OF PROFESSIONAL EXPERI-ENCE IN THIS INDUSTRY. (2) WE ARE THE GOLD SUPPLIER FOR ALIBA.BA.COM

O: WHAT IS THE MINIMUM ORDER OUANTITY?

A: ONE TON WILL DO.

O: ARE YOU A MANUFACTURER OR A TRADING COMPANY?

A: WE ARE THE MANUFACTURER OF MOST OF THE SIZES LISTEDABOVE AND CAN ALSO ASSIST CUSTOMERS WITH THE WHOLE PACK.AGE IF REOUIRED.

O:WHERE IS YOUR FACTORY IN CHINA?

A:DAOU, GUANGPING TOWNSHIP, DONGCHANGFU DISTRICT, LIAOCHENG CITY,SHANDONG PROVINCE

Q:DO YOU HAVE A CERTIFIED QUALITY

A:OF COURSE,ISO 9001:2015

Industrial Valves

Home » Inquiry