Industrial Valves

Home » Inquiry

High quality galvanized corrugated steel sheet

Galvanized Corrugated Steel Sheet: A Comprehensive Introduction

Galvanized corrugated steel sheet, a versatile and resilient material, is widely utilized in various applications due to its unique combination of properties. The process of galvanization involves coating the steel with a protective layer of zinc, enhancing its corrosion resistance and durability. This makes it an excellent choice for outdoor applications and environments with high humidity.

The corrugated design of the steel sheet adds to its strength and rigidity. The ridges and valleys create a strong structural support, making it ideal for roofing, siding, and other architectural applications. The corrugated structure also allows for efficient drainage, preventing water pooling and further enhancing its durability.

In addition to its physical properties, galvanized corrugated steel sheet is also known for its economic benefits. It is cost-effective compared to other roofing and siding materials, offering a long-lasting solution without the need for frequent replacements or repairs. Its durability and resistance to weathering make it a cost-saving investment in the long run.

Moreover, galvanized corrugated steel sheet is environmentally friendly. The zinc coating is recyclable, reducing the impact on the environment. Its long lifespan also means fewer resources are needed to produce replacements, further reducing its environmental impact.

In conclusion, galvanized corrugated steel sheet is a robust, reliable, and economical material that offers numerous benefits. Its corrosion resistance, strength, durability, and environmental friendliness make it a popular choice for a wide range of applications.

Are you looking for quality steel?

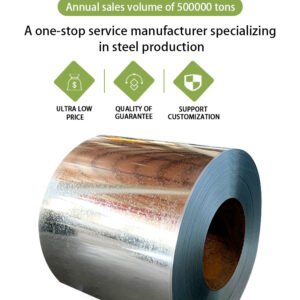

Shandong Jindailai Steel Co., Ltd. is a manufacturer of carbon steel, galvanized steel, profiles and other types of steel manufacturers. Our factories comply with Chinese GB standards and customer specific requirements, products are sold all over the world, steel is widely used in construction, oil and other industries.

Subscribe For Newsletter

Sign up now for updates about early registration. A wonderful serenity taken possession into entire soul also like.

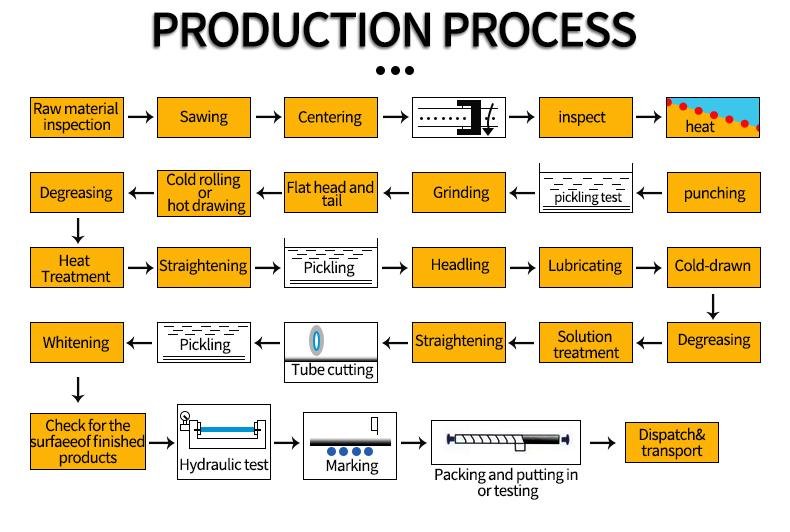

Technological process

The production process of galvanized corrugated board usually includes the following main steps:

Raw material preparation: The main raw materials of galvanized corrugated board are galvanized sheet coil and color coated sheet coil. These raw materials need to be uncoiling, cutting, trimming, opening and other processing to prepare for the subsequent production process.

Steel plate decontamination and pretreatment: The surface of the steel plate needs to be cleaned and decontaminated to ensure the smooth progress of the subsequent process.

Forming: Forming is the core of the production of galvanized corrugated board.

Galvanizing process: Galvanizing is to immerse the steel plate in a molten zinc tank, in this process, the steel plate will chemically react with the molten zinc to form a solid zinc alloy coating, thereby protecting the steel plate from corrosion.

Cooling and cleaning: After the completion of galvanizing, the galvanized sheet needs to be removed from the molten zinc for cooling treatment and surface cleaning.

Cutting and finished product treatment: Finally, galvanized corrugated panels need to be cut and finished product treatment.

It should be noted that in the production process of galvanized corrugated board, attention needs to be paid to protect the environment and ensure production safety.

Applied range

The specific application scenarios of galvanized corrugated board include but are not limited to the following situations:

Construction industry: In the construction industry, galvanized corrugated board has a wide range of applications. It can be used for building roofs, exterior walls, ceilings and roof structures to provide effective protection for buildings. Its good corrosion resistance and weather resistance can effectively resist the erosion of the climate and environment, and extend the service life of the building. In addition, galvanized corrugated panels also perform well in heat and sound insulation, providing a more comfortable environment for the building.

Packaging field: Galvanized corrugated steel plate has good corrosion resistance and wear resistance, and also has a wide range of uses in the packaging field. It can be made into a variety of different types of packaging boxes, boxes, for the transport of goods and commodities.

Industrial Valves

Home » Inquiry

Customized service

Our steel pipe products are tailored to meet the specific requirements of our customers. Whether it’s size, material thickness, or coating, we can tailor it to your unique needs. Shandong Jintai Lai takes pride in the quality of its products. We adhere to strict quality control standards to ensure that our steel pipes are durable, reliable and meet international standards. With many years of experience in the steel industry, we have the knowledge and expertise to provide you with the best solution. Our team of experts is ready to help you with any questions or concerns.

Corrosion resistance is a crucial factor in the selection of pipes for various applications. Our carbon steel pipes are treated with advanced corrosion-resistant coatings and finishes that provide superior protection against rust and other forms of corrosion. This ensures that our pipes maintain their structural integrity and performance over extended periods of use, even in corrosive environments. The corrosion resistance of our pipes significantly reduces maintenance costs and downtime, making them a cost-effective choice for long-term use.

High cost performance and quality service

We offer competitive prices for our steel pipe products, ensuring you get the best value for money. Our wholesale business model allows us to offer discounts for bulk orders, making it more cost effective for our customers.We believe that customer satisfaction is our top priority. Our team is committed to providing exceptional customer service, from initial consultation to after-sales support. We are always ready to help and ensure that your needs are met.

We understand that choosing the right pipes for your application is crucial, and we are committed to providing you with the necessary support and guidance. Our team of experts is available to assist you in selecting the most suitable pipes for your specific requirements. Additionally, we provide comprehensive after-sales support, including installation advice, troubleshooting, and maintenance recommendations. Our reliable customer support ensures that you have a smooth and satisfactory experience with our carbon steel pipes.

Industrial Valves

Home » Inquiry

FAQ

Q: CAN WE VISIT YOUR FACTORY?

A: WARM WELCOME. ONCE WE HAVE YOUR SCHEDULE, WE WILL ARRANGE A PROFESSIONAL SALES TEAM TO FOLLOW UP WITH YOU.

Q: WHAT ARE YOUR PAYMENT TERMS?

A: WE PREFER TT

Q: CAN YOU PROVIDE SAMPLES?

A:YES, THE SAMPLE OF NORMAL SIZE IS FREE, BUT THE BUYER HAS

TO PAY THE FREIGHT.

O: WHY DID YOU CHOOSE OUR COMPANY?

A:(1) WE HAVE MORE THAN 20 YEARS OF PROFESSIONAL EXPERI-ENCE IN THIS INDUSTRY. (2) WE ARE THE GOLD SUPPLIER FOR ALIBA.BA.COM

O: WHAT IS THE MINIMUM ORDER OUANTITY?

A: ONE TON WILL DO.

O: ARE YOU A MANUFACTURER OR A TRADING COMPANY?

A: WE ARE THE MANUFACTURER OF MOST OF THE SIZES LISTEDABOVE AND CAN ALSO ASSIST CUSTOMERS WITH THE WHOLE PACK.AGE IF REOUIRED.

O:WHERE IS YOUR FACTORY IN CHINA?

A:DAOU, GUANGPING TOWNSHIP, DONGCHANGFU DISTRICT, LIAOCHENG CITY,SHANDONG PROVINCE

Q:DO YOU HAVE A CERTIFIED QUALITY

A:OF COURSE,ISO 9001:2015

Industrial Valves

Home » Inquiry