Industrial Valves

Home » Inquiry

High quality galvanized strip produced in China

Galvanized steel strip is a widely used industrial material that is characterized by its superior corrosion resistance and durability. It is produced by coating a layer of zinc or zinc alloy onto a long and narrow strip of cold-rolled or hot-rolled steel. This process, known as galvanization, involves immersing the steel strip in a molten zinc bath, allowing the zinc to adhere to the steel surface through a chemical reaction.

The resulting galvanized steel strip offers numerous benefits, including a uniform zinc coating that ensures even protection, strong adhesion of the coating to the steel base, and a long service life. The zinc coating forms a protective barrier that prevents corrosion and rusting, even in harsh environments.

Galvanized steel strip is commonly used in a variety of applications, such as the construction of pipes for water, gas, and heating systems. It is also used in the manufacture of various industrial components and structures that require resistance to corrosion. In addition, it finds applications in the automotive industry, where it is used to produce corrosion-resistant parts.

The production process of galvanized steel strip involves several steps, including surface preparation, cleaning, and galvanization. The steel strip is first cleaned to remove impurities and then passed through a series of chemical baths to prepare the surface for galvanization. Finally, it is immersed in the molten zinc bath, where the zinc coating is applied.

Are you looking for quality steel?

Shandong Jindailai Steel Co., Ltd. is a manufacturer of carbon steel, galvanized steel, profiles and other types of steel manufacturers. Our factories comply with Chinese GB standards and customer specific requirements, products are sold all over the world, steel is widely used in construction, oil and other industries.

Subscribe For Newsletter

Sign up now for updates about early registration. A wonderful serenity taken possession into entire soul also like.

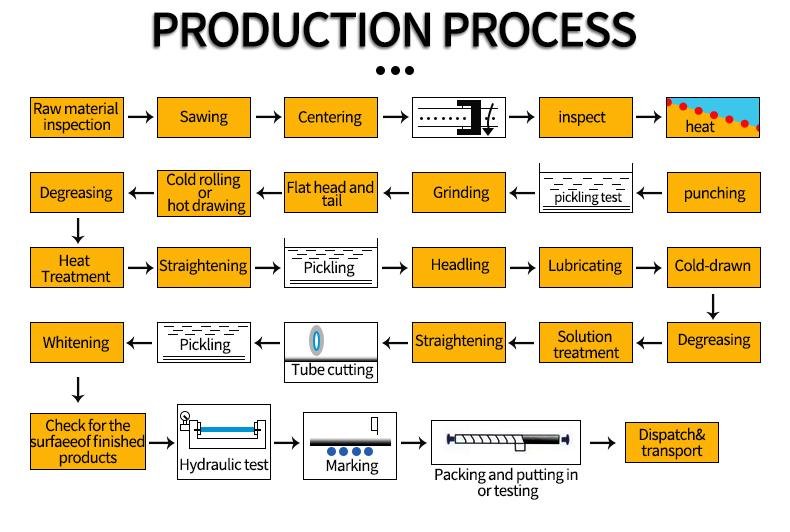

Technological process

Raw material preparation: Select high-quality ordinary steel plate as raw material to ensure that its surface is smooth, free of scratches and oxides.

Raw material cold-rolled plate processing: cold-rolled plate after pickling, rolling, annealing and other processes, become suitable for making strip metal sheet.

Surface treatment: First pickling treatment, remove the surface of the steel sheet oxide and rust. Then phosphating is carried out to prevent the zinc layer from falling off.

Galvanizing treatment: The galvanizing process of galvanized strip steel usually adopts hot dip galvanizing or electric galvanizing technology.

Cold coiling and cutting: Galvanized strips undergo a cold coiling process to achieve the desired specifications and thickness. The strip is then cut and cut to different sizes according to the customer’s requirements.

Post-treatment: The post-treatment of galvanized strip steel includes steps such as passivation, pre-phosphating and oiling. Packaging and shipping: Finally, the galvanized strip is packaged and labeled, and the finished product is shipped to the destination according to the customer’s order requirements.

After these steps are completed, the production process of galvanized strip steel is over. In the production process, the quality of each link needs to be strictly controlled to ensure that the performance and quality of the final product meet the requirements.

Applied range

Galvanized strip steel has a wide range of applications in many fields. The following are some of the main application scenarios of galvanized strip steel:

Construction field: Galvanized strip steel is widely used in the construction field, including building structures, roofs, walls and so on. It can be used as the support of building frames, bridge supports and other structures to increase the stability and carrying capacity of the structure. Industrial field: In the industrial field, galvanized strip steel can be used to manufacture pipeline systems in petroleum, chemical, electric power and other fields, as well as stamping materials.

In general, galvanized strip steel with its anti-corrosion protection performance and a wide range of application fields, in construction, transportation, home appliances, agriculture, industry and other fields play an important role.

Industrial Valves

Home » Inquiry

Customized service

Our steel pipe products are tailored to meet the specific requirements of our customers. Whether it’s size, material thickness, or coating, we can tailor it to your unique needs. Shandong Jintai Lai takes pride in the quality of its products. We adhere to strict quality control standards to ensure that our steel pipes are durable, reliable and meet international standards. With many years of experience in the steel industry, we have the knowledge and expertise to provide you with the best solution. Our team of experts is ready to help you with any questions or concerns.

Corrosion resistance is a crucial factor in the selection of pipes for various applications. Our carbon steel pipes are treated with advanced corrosion-resistant coatings and finishes that provide superior protection against rust and other forms of corrosion. This ensures that our pipes maintain their structural integrity and performance over extended periods of use, even in corrosive environments. The corrosion resistance of our pipes significantly reduces maintenance costs and downtime, making them a cost-effective choice for long-term use.

High cost performance and quality service

We offer competitive prices for our steel pipe products, ensuring you get the best value for money. Our wholesale business model allows us to offer discounts for bulk orders, making it more cost effective for our customers.We believe that customer satisfaction is our top priority. Our team is committed to providing exceptional customer service, from initial consultation to after-sales support. We are always ready to help and ensure that your needs are met.

We understand that choosing the right pipes for your application is crucial, and we are committed to providing you with the necessary support and guidance. Our team of experts is available to assist you in selecting the most suitable pipes for your specific requirements. Additionally, we provide comprehensive after-sales support, including installation advice, troubleshooting, and maintenance recommendations. Our reliable customer support ensures that you have a smooth and satisfactory experience with our carbon steel pipes.

Industrial Valves

Home » Inquiry

FAQ

Q: CAN WE VISIT YOUR FACTORY?

A: WARM WELCOME. ONCE WE HAVE YOUR SCHEDULE, WE WILL ARRANGE A PROFESSIONAL SALES TEAM TO FOLLOW UP WITH YOU.

Q: WHAT ARE YOUR PAYMENT TERMS?

A: WE PREFER TT

Q: CAN YOU PROVIDE SAMPLES?

A:YES, THE SAMPLE OF NORMAL SIZE IS FREE, BUT THE BUYER HAS

TO PAY THE FREIGHT.

O: WHY DID YOU CHOOSE OUR COMPANY?

A:(1) WE HAVE MORE THAN 20 YEARS OF PROFESSIONAL EXPERI-ENCE IN THIS INDUSTRY. (2) WE ARE THE GOLD SUPPLIER FOR ALIBA.BA.COM

O: WHAT IS THE MINIMUM ORDER OUANTITY?

A: ONE TON WILL DO.

O: ARE YOU A MANUFACTURER OR A TRADING COMPANY?

A: WE ARE THE MANUFACTURER OF MOST OF THE SIZES LISTEDABOVE AND CAN ALSO ASSIST CUSTOMERS WITH THE WHOLE PACK.AGE IF REOUIRED.

O:WHERE IS YOUR FACTORY IN CHINA?

A:DAOU, GUANGPING TOWNSHIP, DONGCHANGFU DISTRICT, LIAOCHENG CITY,SHANDONG PROVINCE

Q:DO YOU HAVE A CERTIFIED QUALITY

A:OF COURSE,ISO 9001:2015

Industrial Valves

Home » Inquiry