Carbon steel

Carbon steel is an iron-carbon alloy with carbon content between 0.0218% and 2.11%, containing a small amount of silicon, manganese, sulfur, phosphorus and other elements. According to the carbon content can be divided into low carbon steel, medium carbon steel and high carbon steel, each type has its unique mechanical properties and chemical properties, widely used in many industrial fields.

Carbon steel pipe

Carbon Steel Pipes: Applications and Their Significance

Carbon steel pipes, a crucial component in numerous industries, possess numerous attributes that make them an indispensable material in various applications. From their exceptional strength and durability to their resistance to corrosion and pressure, carbon steel pipes are a versatile choice for a wide range of uses. Here, we delve deeper into the various applications of carbon steel pipes and their significant role in various sectors.

In the construction industry, carbon steel pipes are extensively utilized for a multitude of purposes. They serve as the backbone of structural systems, providing support and stability to buildings and bridges. Carbon steel pipes are also commonly used for the installation of electrical wiring and cabling systems, ensuring safe and efficient electricity transmission. Furthermore, they are often employed in the construction of water and gas distribution systems, transporting vital resources to residential and commercial areas. substances. Whether it is Bridges, high-rise buildings or automobiles, chemical equipment, etc., carbon steel pipes provide strong support for the development of all walks of life with their excellent performance.In conclusion, carbon steel pipes are an essential material in various industries, with numerous applications ranging from construction to mechanical engineering, oil and gas transportation, chemical production, and automotive manufacturing.

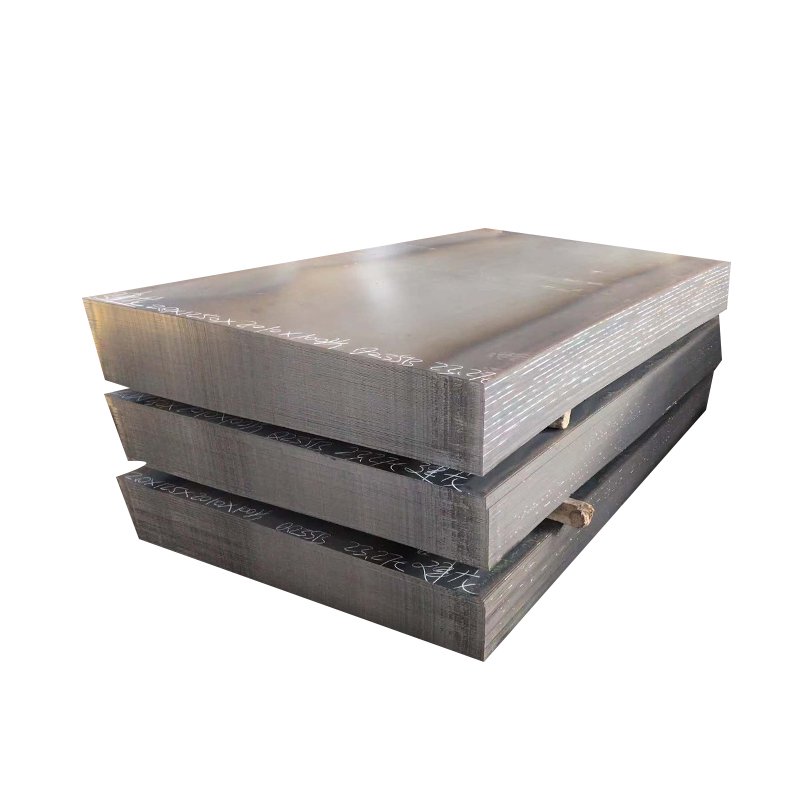

Carbon steel sheet

Carbon steel pipes have significant advantages, including high strength, excellent corrosion resistance, high temperature and low temperature resistance, while its light weight, good processability and relatively affordable price. This makes carbon steel pipes widely used in the construction field, such as as a support and transportation system for building structures; In the mechanical field, carbon steel pipes are used to manufacture various mechanical structures and components; In the petrochemical industry, carbon steel pipes are used to transport oil and gas and chemical substances.

In terms of production process, the manufacturing of carbon steel tubes usually includes perforation, hot rolling, cold rolling or cold dialing steps. First, the solid billet is made into capillary tubes through perforation, and then through hot rolling, cold rolling or cold drawing processes, and finally made into various specifications and shapes of carbon steel tubes. These processes ensure the quality and performance of carbon steel tubes.

Carbon steel roll

Carbon steel coil has significant advantages, its high strength, good toughness and excellent corrosion resistance make it widely used in many fields. The structure of carbon steel coil is tight, the surface is flat, and has excellent mechanical properties and processing properties, which can meet the needs of various complex processes.

In terms of use, carbon steel coil is used in the construction field to make building frames, Bridges and other structural materials; In the field of machinery, it can be used to manufacture various machine parts and tools; In the automotive field, carbon steel coil is an important material for the body, chassis and other key parts. In addition, carbon steel coil is also widely used in aviation, energy, chemical and other fields.

In terms of production process, carbon steel rolls are usually made by hot rolling, cold rolling and other processes. These processes ensure the quality, performance and dimensional accuracy of carbon steel rolls to meet the needs of different customers and application scenarios.

Carbon steel bar

The advantages of carbon steel rod are mainly reflected in its high strength, good toughness and easy processing. Due to its high carbon content, carbon steel rods have excellent hardness and wear resistance, and are able to maintain stable performance in a variety of harsh environments.

Carbon steel rods have a wide range of uses, mainly for strengthening concrete structures, Bridges and building support, as well as manufacturing mechanical parts, bearings, gears, etc. In addition, it can also be used in the manufacture of cutting tools, cutting tools, automotive and aerospace parts.

In terms of production technology, the production of carbon steel rods mainly includes forging, pressure processing and sawing processes. The forging process can produce carbon steel rods with complex shapes, while pressure processing such as rolling can ensure excellent surface quality and dimensional accuracy of carbon steel rods. The sawing process is used to cut carbon steel rods to the desired length and dimensions.

Look forward to cooperating with you!

We always want to make sure that our customers are getting the best deal, so let us know what you’re interested in and we’ll get back with a quote!